I. INTRODUCTION

During the Vietnam War, the US Army used chemical weapons to prevent liberation forces from entering the southern border and territory. Over 19,905 missions of spraying chemicals, 95,112.688 kg of herbicides and more than 9,000 tons of cs, sprayed to 2.63 million hectares, accounting for 15.2% of the total area of South Vietnam.

The US Army used 7 main airbases and other sub airbases for storages and disposal sites for spraying chemicals, which distributed dioxin to the environment. Base on data from US Army and results of investigation had three “hotspot”: Bien Hoa airbase, Phu Cat airbase and Da Nang airbase.

Now, besides applied In Pile Thermal Desorption (IPTD) technologies to treat more than 90,000 m3 contaminated soil in Da Nang airbase; contaminated soil in Phu Cat airbase and part of Bien Hoa airbase were being covered and temporary prevented its effect to environment and people.

Situation of pollution is a hard working need to be find effectively, suitable technologies for remediation the remaining chemicals after Vietnam War.

II. MATERIAL AND METHOD

Results of investigating, experimenting, treating in Vietam and applied tretment technology in Vietnam.

Collect, summarize, assess data of investigation, experiment, treatment in Vietnam.

III. RESULTS AND DISCUSSION

3.1. Research, experiment technology

In the world, there are several technical solutions that studied for treatment of the toxic compounds, especially for POPs, PCB, dioxin and furan. In which, a few technologies were tested for treatment of dioxin-contaminated soil and sediment in Vietnam: 50 kg soil were tested in Thermodyne laboratory using the thermal desorption technology MCS by Thermodyne group (USA) in 2012; 100 tons soil using ball-ground of New Zealand in 2012.

In addition, there were a lot of researches on dioxin treating solutions, the representative are: Research project \"Study landfill technology for conditions of Vietnam\" by Chemical Defense Command, completed in 2003 and applied for landfill 150,000 m3 of contaminated soil at Bien Hoa airbase and Phu Cat airbase; Research project “Study and select suitable technology for treatment of dioxin-contaminated soil and sediment in Vietnam\'s conditions” by Ph.D. Lam Vinh Anh (Chemical Defense Command) has successfully researched and pilot model tested with a capacity of 50 kg/h. This is a very promising research and can be scaled up in practice.

Besides, there are some dioxin treatment studies by other foreign scientists: “Study on dioxin treatment by biodegradation” of Assoc. Prof. Dang Thi Cam Ha (Institute of Biological Technology); “Treatment of dioxin by aerobic and anaerobic bacteria” by Korean Experts and Association for Nature and Environment Protection; “Treatment of dioxin by Vetiver” of Ph.D. Ngo Thi Thuy Huong (Vietnam Institute of Geology and Minerals); “Treatment of dioxin in the gas phase by oxidation catalysis” of Assoc. Prof. Vu Anh Tuan (Vietnam Academy of Science and Technology); and some studies of other theses and dissertations.

The results of those experiments and studies are relatively positive, open the promising way but need more experiments to be applicable in practice and more study on a larger scale to confirm as well as optimize technological parameters.

Currently, Center for Technology Environmental Treatment/Chemical Defense Command co-ordinate with partners to test the treatment of 1,000 tons of soil contaminated by soil washing technology (Japan) and 1,000 tons of soil/sediment contaminated by in pile thermal desorption technologies and in site thermal desorption technologies by Heamer Group\'s (Belgium), expected to completed in 2019.

3.2. Applied treatment technologies

Pioneers in treatment technologies and prevents spillover pollution is “Landfill technology” by the Center for Technology Environmental Treatment/Chemical Defense Command, which were studied and applied. This technology has successfull treated 94,000 m3 contaminated soil in Z1 area from 2006 - 2010 (Project XD-1), and continues to treat about 60,000 m3 contaminated soil in the Ballpark area and Z1 spill area from 2013 - 2016 (Project XĐ-2). This technology is also highly appreciated by Office of National Steering Committee 33 and was successfully applied to treat 7,500 m3 contaminated soil at Phu Cat airport. However, Landfill is not a completely treatment technology. This technology prevents spillover pollution to environment.

Beside Landfill technology, thermal desorption technology had applied with a capacity of 45,000 m3/pile at Da Nang airbase, the total 90,000 m3 of contaminated soil/sediment had treated. Up to now, this project basically completes and achieves treated goal, but this is a high costs technology and expose secondary waste.

3.3. Introduce some dioxin treatment technologies in Vietnam

3.3.1. Module Thermal Desorption Technology, MCS

MCS technology is copyrighted by Thermodyne Technologies, Inc. (TO), a pollution treatment company, headquarter in North Carolina.

The Thermodyne Technology Group was founded in 1998, a supplier for US government and private company in environmental pollution treatment services, new solutions and recycle technology used for hazardous solid waste tretament which was previously treated by landfill or burning.

The engineers and specialists of Thermodyne Technology Group have in-depth knowledge and long-time experience of environmental treatment technologies, which include traditional technologies as well as new breakthrough technologies applied for pollution treatment and recovery solid waste. Thermodyne Technology Group has special expertise in low temperature vacuum extraction, distillation technology, and separation technology.

The Thermodyne Technology Group owns the proprietary rights to the low temperature release absorption technology called MCS. MCS technology is environmentally-friendly, proven technology that is effective in treating industrial waste and soil contaminated by various chemicals. MCS technology has been successfully used in many governments and US military missions for cost-effective purposes. Some typical tasks performed in the United States are as follows:

MCS technology has been successfully treated 15,000 tons soil-contaminated herbicides and PCP in North Carolina, USA. The level of soil-contaminated at the threshold of 10,000 ppm has been lowered to less than 1 ppm for herbicides and 3.2 ppm for PCP.

For treatment of hazardous waste, MCS technology has been successfully applied at Nevada. The treatment scopes includes a wide range of hazardous wastes from various industrial sources including herbicides, BTEX, VOCs, SVOCs, TPHs, PAHs

For treatment of hazardous waste in Colorado, MCS technology has treated 5,500 tons contaminated soil and wastes containing radioactive elements such as americium, uranium, and plutonium.

Some of the international tasks that Thermodyne has processed 10,000 tons soil-contaminated residue from oil extraction and processing operations in Malaysia. Following the success of the mission, the Malaysian Government continues to use MCS technology in other tasks to treat contaminated soils from different levels in Malaysia.

In Taiwan, MCS technology was used to treat 6,000 tons soil and industrial mercury-contaminated waste at a plastic plant from Formosa Group near Cao Hung city.

Task was successfully and reduced the level of mercury-contaminated from 1,000 ppm to less than 2 ppm.

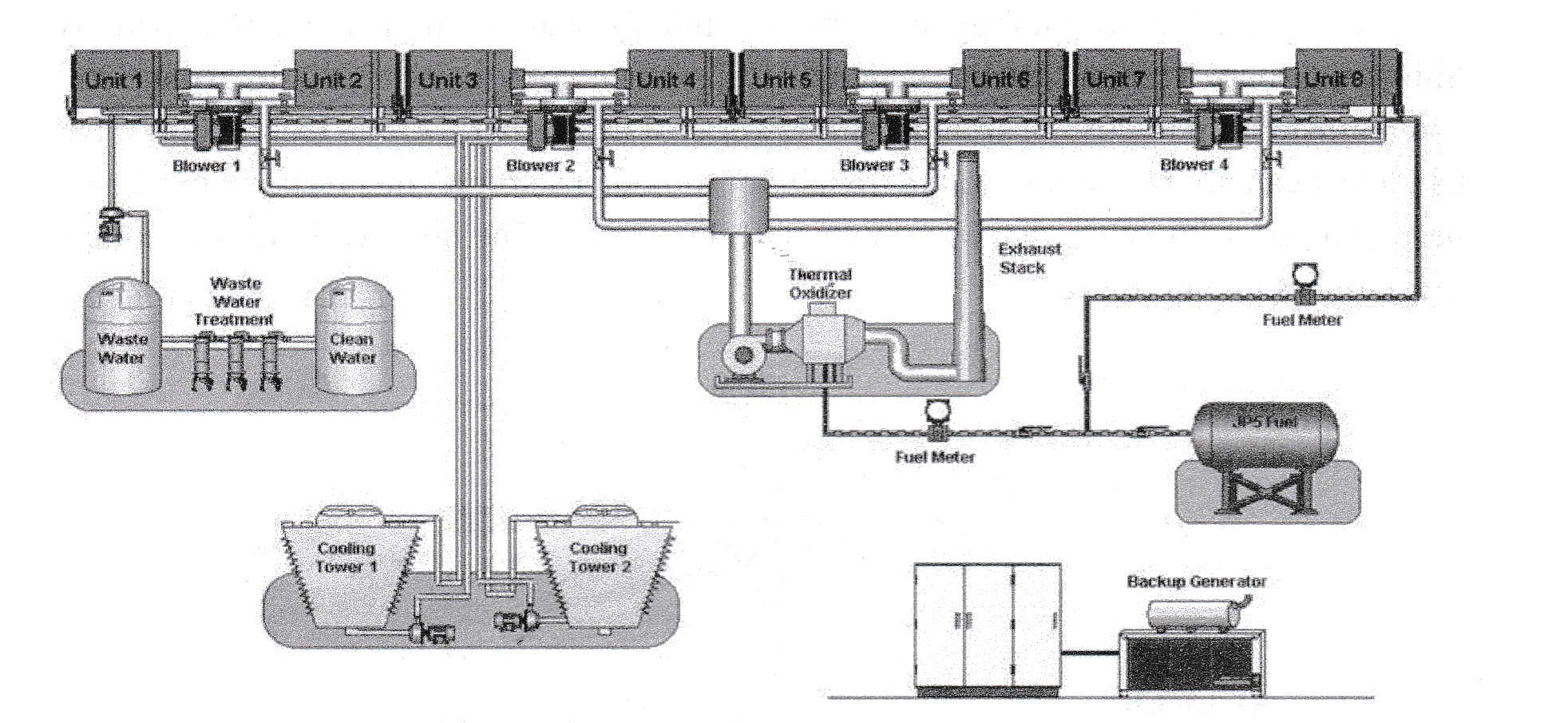

In the field of dioxin treatment, this technology has been used to treat 24,000 tons agent orange/dioxin-contaminated soil in Jonhston (USA) and also has been tested in the laboratory with 50 kg of contaminated soil from Bien Hoa airbase. The results showed that this technology has the ability to process up to over 99%. The technology diagram is depicted in figure 1 below.

Dioxin in contaminated soil is desorption, transferred to the vapor phase of heating unit and then completely oxidized in the thermal oxidizer before being released into the environment.

Contaminated soil after desorption, separates more than 99% of dioxin and other evaporative toxins are cooled and come out of treatment system, can be used as landfill soil or add more nutrients for use in agriculture.

|

Figure 1. Technological diagram MCS

This treatment system is designed in module structure, independently operate, easy to disassemble and can be combined to increase treatment capacity. The energy using for heating system is electricity. Estimated cost of treatment is approximately equal to IPTD technology currently applied at Da Nang airbase.

This technology has several advantages: Allows efficient treating with many different types of pollutants; optional heating options (electricity, LPG, NPG, diesel...); good quality control of waste gas and waste water. However, this technology has high cost, almost equal to IPTD technology was applied at Da Nang airbase.

3.3.2. Soil washing technology

Shimizu Group was founded in 1804, is a leading company in Japan in the fields of construction, manufacturing and industry. In 2003, the new environmental law came into force in Japan to prevent contaminated soil and water from industrial activities. Shimizu Group pioneered, installed and commissioned the first industrial land-washing treatment system. During the operation, Shimizu Group continuously improves its equipment, improving soil washing technology to treat soil-contaminated various types of agents such as heavy metals, mineral oils, cyanides, pesticides. In 2009, Shimizu Group\'s fixed-line washing facilities successfully treated 1.100.000 tons contaminated soil.

In 2004, Shimizu Group made a significantly improvement, designed a mobile land treatment system capabled of handling the same fixed treatment system. This soil treatment system can be customized to handle a wide variety of pollutants. Up to now, Shimizu\'s mobile treatment system has been operating extensively throughout Japan.

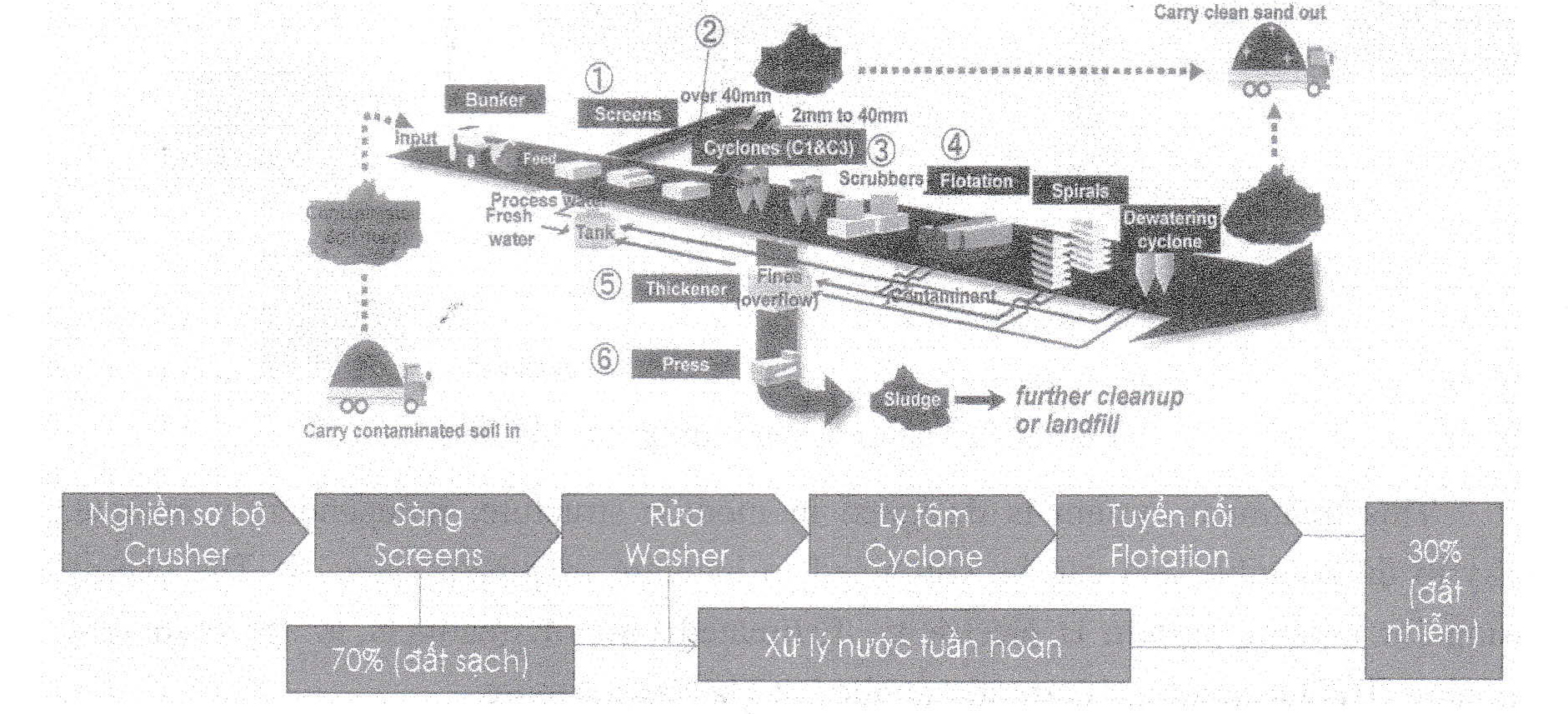

The washing technology of toxic chemicals was studied and developed by Shimizu Group. The outstanding feature of this technology is its ability to reduce soil contamination up to 70% of weight with lower cost than other thermal technologies, but the defect can not be eliminated the toxicity of dioxin. Therefore, this technology should be combined with other dioxin treatment technologies. The soil washing technology diagram is show in figure 2.

|

Figure 2. The diagram of Shimizu washing technology

According to this technological diagram, dioxin-contaminated soil was grounded and sieved to facilitate the process of washing agent orange/dioxin out of the soil by suitable solvent system. After that, the washing soil is separated from the solution by centrifugal filtration, flocculation, soil washing process removes about 70% contamination soil, the remaining 30% of dioxin will be treated by other methods. The washing solution is circulated, to minimize the amount of polluted discharged to environment. The amount of clean soil after treatment (70% of weight) does not change the physical properties, so it can be reused for other purposes as clean soil.

This technology has several advantages: Lower cost than other technologies, because it does not consume too much energy, but the biggest disadvantage is not effective when treating sludge and can not be eliminated of dioxin toxicity. It should be combined with other technologies.

3.3.3. Thermal desorption technology

Haemer Group is one of the leading Defense technology groups in Israel. Haemer Group has a history of 80 years, which owns subsidiaries such as IWI, Meprolight, Camero, ous, Israel Shipyards..., providing various defense products such as personal weapons, optical view technology learning and laser, tracking, simulation, etc. All of the company\'s products are on Israeli Defense Ministry equipment. In the international field, Haemer Group provides products and services to more than 40 countries. Haemer Group has experience in performing large-scale tasks with the Ministry of Defense of Vietnam such as the task of transferring technology lines to Vietnam at the Z111 plant.

LDD advanced technologies is an important partner of Haemer Group, which has been active in the field of decontamination for 18 years. The company owns a larger amont of expertise, engineers and technician and has many patents of advanded technologies. LDD undertakes a variety of different tasks of decotamination and evinromental treatment from survey, consultancy, design and treating. The technology solutions offerd by the company are capable of on-site or centralized processing and all have common characteristics that are cost-effective very competitive.

LDD holds a 75% market share in the Israel remover and performs more than 500 missions around the world. There are 1,000,000 tons of concentrated waste and 10,000,000 tons of waste treated on the spot. Some of the key remediation tasks that the company has done include landfill and groundwater treatment of TCE (tricloethylene) in central Tel Aviv, lowering the level of toxicity from 14,300 ppb to under 50 ppb, The task of handling 700 contaminated TPH land from industrial activity at a factory in northern Israel. Dealing with 2,500 m2 of BTEX and MTBE contaminated land in central Israel. LDD has also conducted land level surveys for the Israel government and is currently the contractor for the operation of the Waste Collection and Treatment Facility National Hazard to the Government of Israel.

LDD is the only company to carry out the DoD missions of the Israel Defense Ministry from 2010, under a contract that lasts until 2019. Currently, the LDD is a contractor to the Israeli Defense Forces and Army. Completion of survey and evaluation reports in military and industrial areas serving the military. Estimated cost of land clearance in central Israel is 675 million USD (2017 - 2022).

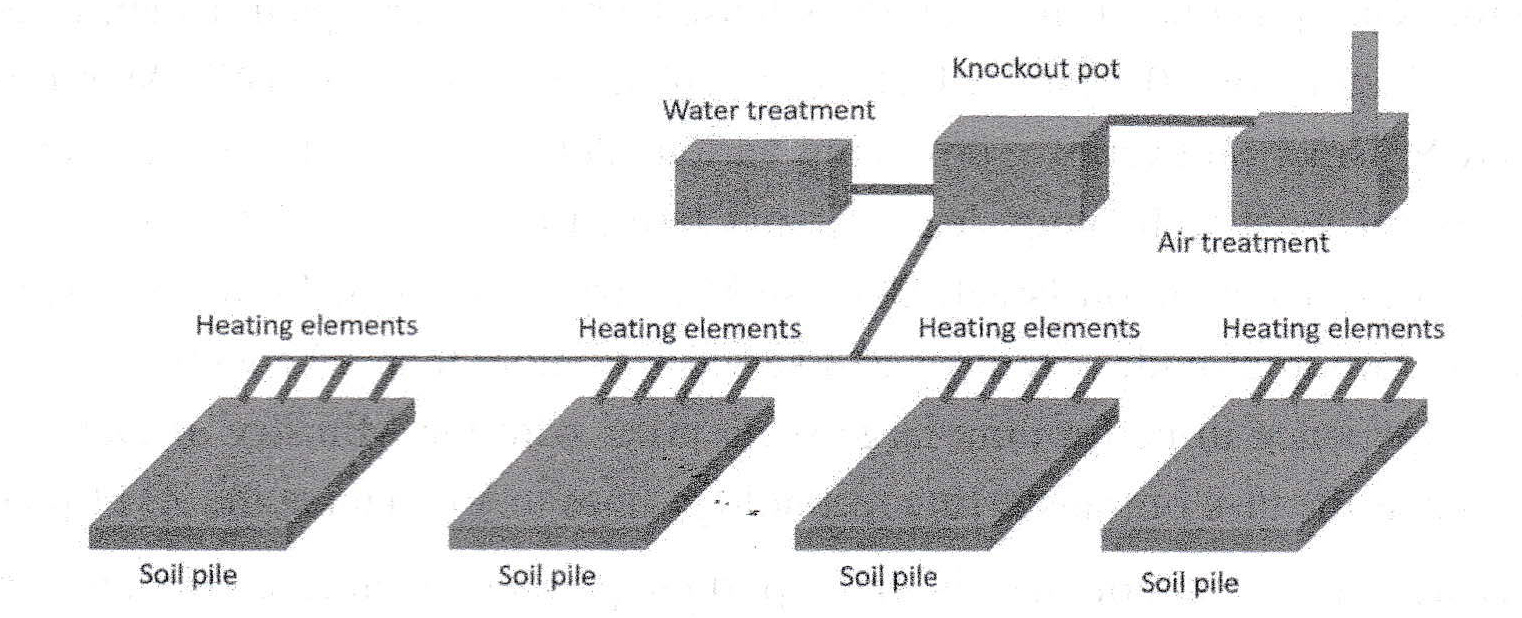

Haemer Group and LDD partner propose to treat dioxin contaminated soil at Bien Hoa airbase by thermal desorption technology. This technology has been applied in more than 30 different tasks to treat contaminated POPs. The nature of Haemer and LDD\'s heat treatment technology is similar to that of IPTD technology which is currently applying dioxin contaminated soil at Danang airbase. The technology is depicted in figure 3 and figure 4 below.

|

Figure 3. Haemer Group Land Treatment Technology diagram

According to this technology map, the company\'s approach is to divide dioxin contaminated soil into groups of varying levels of pollution. Each group will be placed in a separate desulfurization chamber and optimized for the heat treatment of each subject.

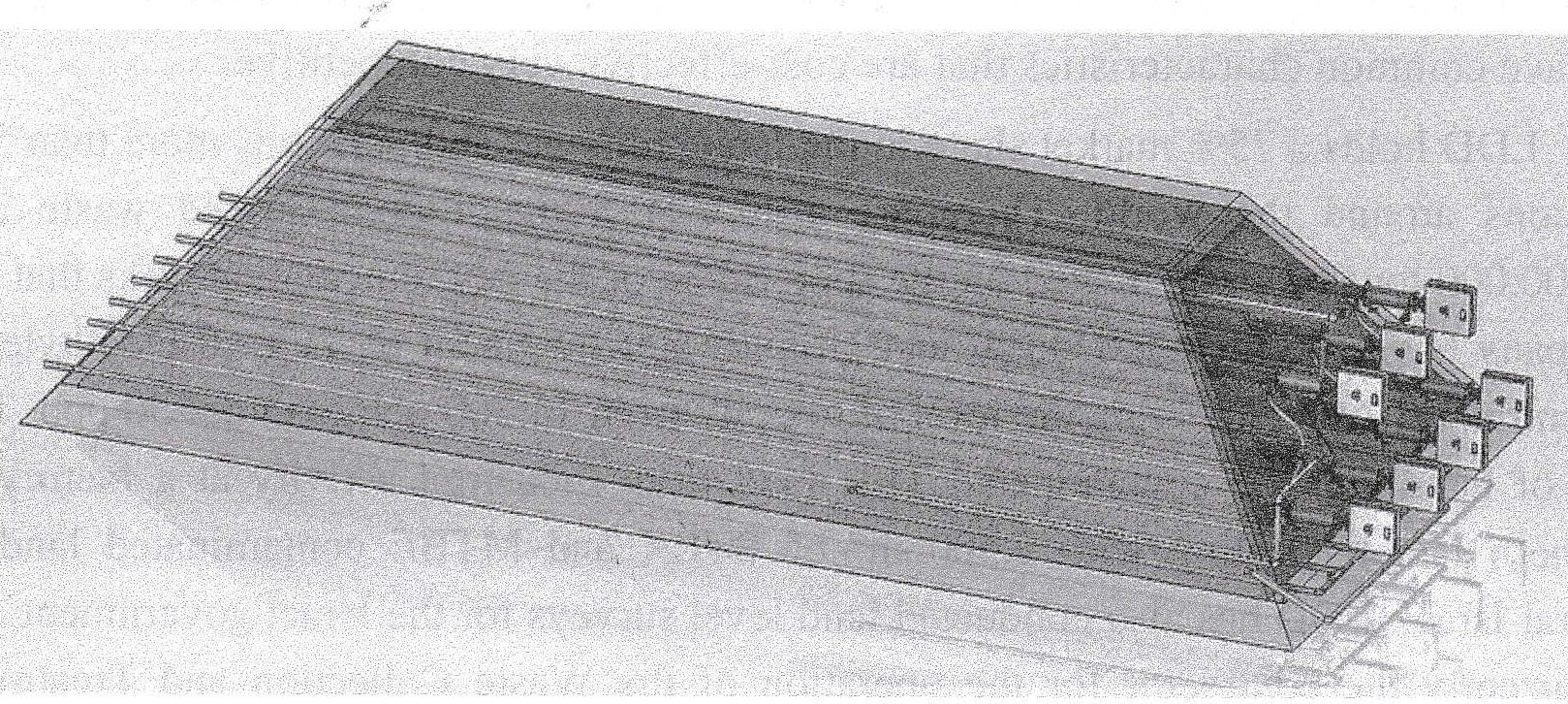

|

Figure 4. Diagram of a landfill of Haemer Group

The advantage of the technology is that it separates the soil treatment objects into different abrasives and is optimized for heat treatment so that the size of the abrasives is small, thereby improving the efficiency of the treatment and removal costs short time to process. In addition, the technology allows for flexible customization of the site\'s processing terrain and greater flexibility than IPTD in the treatment of contaminated soil.

The technology used is thermal desorption technology, so it has the advantages of this technology, specifically technology has been applied dioxin treatment in large quantities; high performance; dust treatment, which is capable of operating flexible treatment for specific pollutants by using temperature programs for each treatment module. This will increase the energy efficiency as well as improve the efficiency of the process. It is possible to customize the volume increase or decrease during batches, which can easily meet the processing requirements when there is an increase or decrease in mass compared to the initial estimate. This technology compares to IPTD technology at Da Nang airbase, this technology has smaller scale and greater flexibility due to the equipment layout.

IV. CONCLUSION

Untill now, studying and screening technology to select scientific and relistic solutions, in order to completely treat dioxin, return the safety environment for Bien Hoa airbase area, remove the risk of exposure and toxic effects on human health, strengthen the stability of national security is a urgent demand. However, the efficiency of the mentioned testing technologies is still ahead, the technology has been applied also many issues to discuss and complete.

In the future, together with testing and experiencing, it is necessary to continue opening new research direction and solutions of combine technologies to improve treatment efficiency. Extending application in industrial dioxin and other toxic wastes, contributing for development of the environmental industry, towards sustainable development is a right direction, receiving the attention from the Government. Additionally, the pioneering role of soldiers in the peacetime is indispensable.

REFERENCES

1. Báo cáo tổng kết dự an Zl, 72,73,79 và Dự án XD-1, Trung tâm Công nghệ Xử lý Môi trường, 2012.

2. Lê Ke Son (2013), Báo cáo tong the’về tình hình ô nhiễm dioxin tại 3 điếm nóng sân bay Biên Hòa, Đà Nang và Phù Cát, Văn phòng Ban chỉ đạo 33, Bộ TN&MT

3. VACNE. 2017. Báo cáo kết quả thừ nghiêm tay độc dioxin bằng phương pháp vi sinh Hàn Quốc tại sân bay A Sho, A Lưới. 8-2017

4. Nguyễn Hùng Minh (2012), Đánh giá bổ sung ô nhiễm dioxin tại các khu vực ô nhiễm mới được phát hiện ở sân bay Biên Hòa và Phù Cát, phòng thí nghiệm dioxin, Tổng cục Môi trường Việt Nam.

5. USAID (2016), Đánh giá môi trường ô nhiêm dioxin tại sân bay Biên Hòa, Dự án hợp tác giữa Bộ Quốc phòng Việt Nam và Cơ quan phát triển Hoa Kỳ.

6. Hoàng Bá Thịnh (201 ỉ), Nạn nhân chất da cam/dioxin ở Việt Nam và nỗi lo về thế hệ tương lai, Nhà xuất bản trẻ, TP Hồ Chí Minh.

7. Đỗ Ngọc Lanh (2012), Nghiên cứu tác động lâu dài của chất độc hoá học chứa dioxin tại khu chứa chất độc trong sân bay Đà Năng đến môi trường và sinh thái, Đe tài thuộc Chưong trình 33.

8. Vũ Chiến Thắng (2010), Tác động của chất độc hóa học của Mỹ sử dụng trong chiến tranh đối với môi trường và con người Việt Nam, Bộ Tài nguyên và Môi trường, Hà Nội.

9. TS. Phạm Ngọc Cảnh “Xử lý ô nhiễm dioxin tại Việt Nam”, Báo cáo tại Hội nghị “Dioxin 28”, London, August, 2008.

10.http://hepa.gov.vn/content/tmtuc_chitiet.php? catid=341&subcatid=0&newsid=354&langid=0.

11.http://www.ued.edu.vn/khoasinh/index.php?option=com__tai-nguyen-va-moi-tmg&Itemid=585.

12. Hatfield Consultants and Office of the National Committee 33 (2007), Assessment of Dioxin Contamination in the Environment and Human Population in the Vicinity of Da Nang Airbase, Viet Nam Final report.

Tran Due Hung 1

1. Military Institute of Chemical and Environment, Chemical Defense Command

_thumb_720.jpg)

_thumb_720.jpg)

.png)

Comment